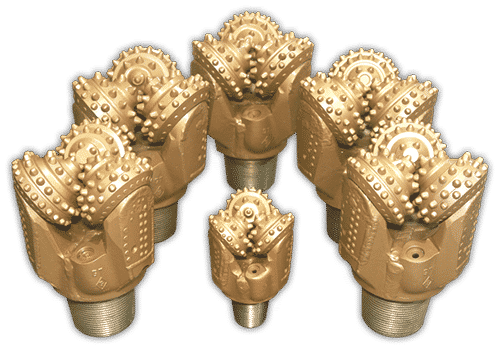

Tri-Cone Bits

For Rotary & Motor Applications

Century Products offers a full line of made in the USA Tri-Cone™ Bits in both Tungsten Carbide Inserts (TCI) and Milled Tooth cutting structures. There are a variety of sizes and configurations in both the TCI and Milled Tooth cutting structures which allow our products to be tailored to specific drilling conditions.

Soft Formation TCI Bits

For shales, sandstones, limestones and dolomites

These Tri-Cone™ Bits are designed for maximum penetration rates. Bit tracking is virtually eliminated by combining a large cone offset, sharp chisel-shaped inserts and non-uniform tooth spacing. Shirttail protection along with carbide leg protection increases bit life for HDD applications.

Medium to Hard Formation TCI Bits

For medium-hard shales, limestones, sandstones and dolomites

These Tri-Cone™ Bits have moderately sharp conical or chisel inserts with a shorter extension. An increased insert count helps reduce breakage when drilling in harder formations. Full bottom hole coverage and non-uniform insert spacing results in smooth drilling at high penetration rates.

Hard Formation TCI Bits

For hard sandstones, granites, dolomites, quartzite and pyrites

These Tri-Cone™ Bits are designed to withstand high loads and drill abrasive conditions where rock is broken under high compressive point loads, with little scraping and gouging. Therefore, the cutting elements tend to be small, exhibit shorter protrusion and are more densely packed, which prevents the high compressive loads from breaking the tooth before it breaks the rock.

- Made In The USA

- 3 7/8 – 12 ¼” Size Range

- Multiple IADC Codes

- Sealed Journal Bearing

- Elastomer O-Ring

- Synthetic Formulated Grease

- Shirttail/Leg Protection

- Stainless Steel Nozzle Retaining Rings

- Premium Silver Plated Bushings & Thrust Washers

IADC Code Size Chart

| THREAD SIZE | IADC CENTURY BIT |

4-1-7 CP 04X CP 09X |

4-2-7 CP 12X CP 15X |

4-3-7 CP 11A CP 43X |

4-4-7 CP 18X |

5-1-7 CP 19X CP 20X CP 22X CP 23X CP 24X |

5-2-7 CP 25X CP 25Y CP 28X CP 31X CP 32X |

5-3-7 CP 30A CP 31A CP 33Y CP 35X |

5-4-7 CP 35Y CP 38Y |

6-1-7 CP 40A CP 42X CP 43X |

6-2-7 CP 44X CP 44Y CP 45Y |

6-3-7 CP 50Y CP 55Y CP 63Y |

6-4-7 CP 66Y |

7-2-7 CP 57Y CP 72Y |

|

|

||||||||||||||

| 2 3/8″ API | 3 7/8″ | X | X | X | X | X | ||||||||

| 4 1/2″ | X | |||||||||||||

|

|

||||||||||||||

| 2 7/8″ API | 4 5/8″ | X | ||||||||||||

| 4 3/4″ | X | X | X | X | X | X | X | X | ||||||

| 4 7/8″ | X | X | X | X | ||||||||||

| 5″ | X | X | X | |||||||||||

| 5 1/8″ | X | X | X | X | X | |||||||||

| 5 1/4″ | X | X | X | X | X | X | X | |||||||

| 5 1/2″ | X | X | X | X | X | X | ||||||||

|

|

||||||||||||||

| 3 1/2″ API | 5 5/8″ | X | X | X | ||||||||||

| 5 7/8″ | X | X | ||||||||||||

| 6″ | X | X | ||||||||||||

| 6 1/8″ | X | X | X | X | X | X | X | |||||||

| 6 1/4″ | X | X | X | A | ||||||||||

| 6 1/2″ | X | X | X | A | X | |||||||||

| 6 3/4″ | X | X | X | X | ||||||||||

|

|

||||||||||||||

| 4 1/2″ API | 7 7/8″ | X | X | X | X | X | X&A | X | X&A | X | X | |||

| 8 1/2″ | ||||||||||||||

| 8 3/4″ | X | X | X | X | X | X&A | X | |||||||

| 8 7/8″ | A | |||||||||||||

|

|

||||||||||||||

| 6 5/8″ API | 9 7/8″ | X | X | |||||||||||

| 10 5/8″ | X | X | X | X | ||||||||||

| 11″ | X | X | X | X | A | |||||||||

| 12 1/4″ | X | X | X | X | X | X | X | X | X | |||||

| A=Air Bit | ||||||||||||||