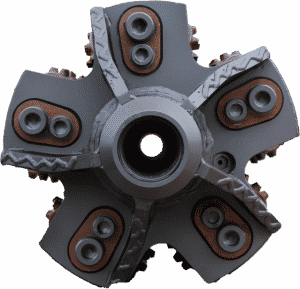

ARM & CONE DESIGN – FALCON FR SERIES

Gage Row

Double the number of tungsten carbide inserts that actively cut the gage diameter and assists in maintaining tight tolerances and extending in-gage bit life.

Gage Row Protection

Provides for longer in-gage bit life.

Shirttail/Leg Protection

Hard Facing along with carbide inserts blanket the shirttail and leg, providing superior wear resistance.

Grease Reservoir

Grease Reservoir for longer bit life.

Arm

Robust, Self-energizing, tapered Joint design.

CENTURY ARM & CONE ASSEMBLY

A Key feature of the Falcon FR Hole Opener is the innovative Field Replaceable Arm & Cone Assembly. Century’s Engineering Team delivered this turn-key, innovative drilling solution utilizing the latest in software design, 3D Modeling, Finite Element Analysis, materials and manufacturing processes. This unique design requires no welding to interchange assemblies right in the field. In addition, key features are incorporated into each assembly that extends the life of every Hole Opener.

Design Features

- Mechanical Bolted Design – simple yet incredibly strong design that requires no welding

- Arm & Cone Compensators – larger grease reservoir for longer bit longevity

- Synthetic Grease – Specially formulated for Century’s sealed roller bearings

High Load, High Energy Cone Configurations

- 12.5″ & 17″

- Tungsten Carbide Insert (TCI) and Milled Tooth configurations

- TCI Conical, TCI Chisel and Milled

Mechanical Bolted Design

The Falcon FR Hole Openers Mechanical Bolted Design makes swapping out assemblies a breeze to do. No more waiting for welded units to be cut out and new assemblies welded in. All that is required is the loosening and tightening of our bolted design – and this can be accomplished right in the field!

Utilizing a robust, self-energizing/self-aligning Dual Pocket Joint Design allows for the correct alignment of assemblies when installing new units into the body.

Drilling Performance

There is a direct correlation between the cone, bearing, seal and carbide insert size to maximizing penetration rates and bit longevity.

Cone Size

Larger cones offer distinct advantages when it comes to drilling. They allow for larger cuts which eliminates passes, larger bearings and seals, and fewer cone revolutions per RPM.

The bottom line effect of these advantages is the time and money saved. Fewer reaming passes combined with fewer cone revolutions as well as the larger bearings and seals allow you to stay on the bottom drilling. The longer you are drilling, the more cost effective your tool becomes.

Bearing Size

Most designs consist of a main roller bearing, ball race, thrust bearing and nose bearing (roller or sleeve). Century’s roller and sleeve designs utilizes the bearings to properly distribute the load across the entire cone face. This prevents the point loading and possible premature bearing failure that results from taking smaller cuts versus the larger cuts Hole Openers with larger cones can take. The larger bearings used allow for greater load capacity as well.

Seal Size

Seal size is a critical component in the design of cones. A larger effective seal area provides the advantage of longer seal life. This, in addition to the composition of seal material, is key to designing seals with a better resistance to compression set and abrasive formation wear which extends the running time of Hole Openers that utilize these types of cones.

Larger Carbide Inserts

In looking at the maximum weight on a bit available due to the torsion limits of the drill string and the amount of weight per insert necessary to break rock, it was determined that a very large carbide insert could be used as long as a full cone cutting structure was achieved. These larger inserts can cut rock effectively even though they have the look of a soft formation tool. This offers greater flexibility for boring in areas where the lithology is not well known because the tool can cut both soft and hard formations efficiently without twisting off.

Cost Effective Tool

An integral component of overall drilling performance is the selection of the correct bit. There are many factors that go into the selection of the best bit for any given formation to be encountered. Century’s Field Replaceable Arm & Cone Assemblies excel in virtually all soil, cobble and rock conditions. This combination, along with the ease of swapping out assemblies right in the field, make the Falcon FR Hole Opener the bit of choice.

Our design features take advantage of the four components that have a direct correlation on maximizing penetration rates and bit longevity. When bottom line performance is what you are looking for, Century’s reputation for long bit life is your answer.