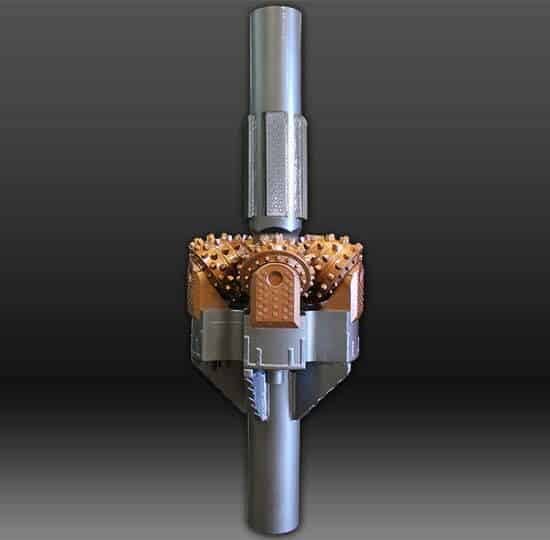

Falcon FR Features and Options

Shaft

Multiple shaft sizes available with 5-1/2″ FHDS | 4-1/2″ I.F. and 3-1/2″ I.F. Box x Box Thread Connections.

Front Stabilizer Bars

Stabilizer Bars facilitate centering the Hole Opener in the bore hole. Carbide Insert Stabilize Bars are standard on the Falcon FR Hole Openers.

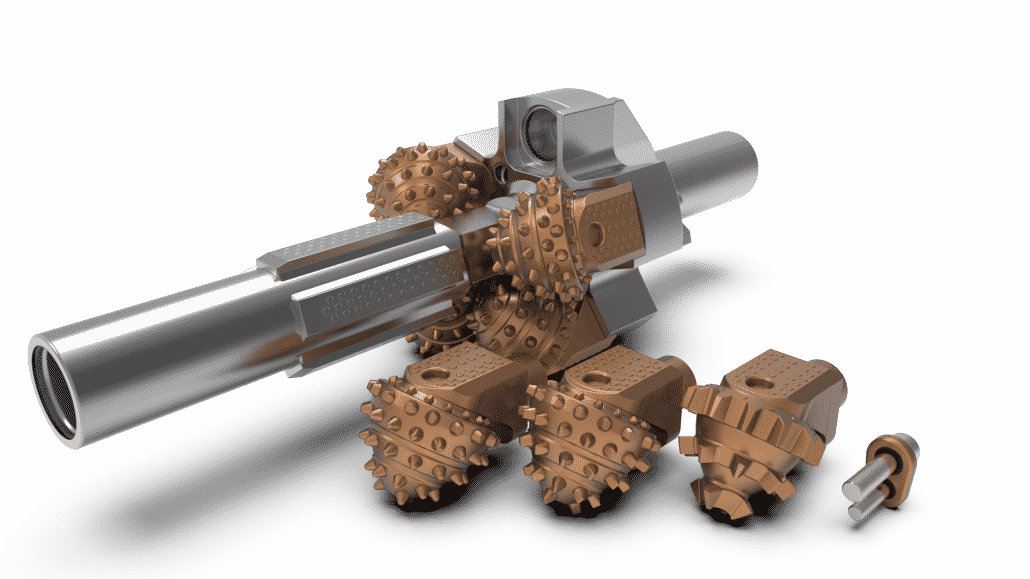

Field Replaceable Assembly

Mechanical Bolted Arm & Cone Assembly requires no welding to interchange Arm & Cone assemblies. Utilizing a Two Bolt design allows for easily changing out one profile for another right on the jobsite.

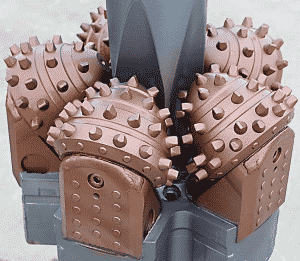

Cutter Configuration

Mechanical Bolted Arm and Cone Assemblies are available in 12.5″ & 17″ bearing sizes for longer downhole time with three different cutting structures incorporating TCI Conical and Chisel profiles as well as Milled Tooth configuration.

Jet Hydraulics

Integrated Fluid Chamber machined into Body to assist in hole cleaning. All Hole Openers incorporate Interchangeable Carbide Jets between each arm assembly as well as a rear body jet to enhance the hole cleaning ability at the face or assist in cutting removal in the rear.

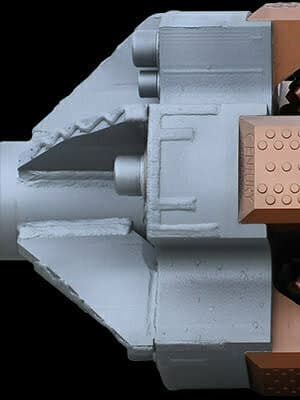

Solid Body

Solid Bodies virtually eliminate cutter flex maximizing the energy directed at fracturing rock. Every solid body is precision machined with a Dual Pocket Joint Design and Integrated Fluid Chamber.

Dual Pocket

Our Dual Pocket design ensures the integrity of Arm & Cone Assemblies.

Rear Gussets

Rear Gussets are standard for increased strength and easy removal from the bore hole. Hard Facing is standard on all gussets.

HOLE OPENER DESIGN – FALCON FR SERIES

With Field Replaceable Assemblies, the Falcon FR puts you in charge of whatever formations you encounter underground. Incorporating Century’s Patent Pending Mechanical Bolted Design the Falcon FR Series allows you to easily interchange Arm & Cone Assemblies – right in the field! No welding required!

Design Features

- Dual Pocket Joint Design

- Mechanical Bolted Arm & Cone Assembly

- Precision Machined Solid Body

- 3-1/2, 4-1/2 I.F. & 5-1/2 FHDS Connections

- Interchangeable Jet Nozzles

Standard Options

- Active Gage Protection

- Shirttail Protection

- Advanced hydraulics features

- Multiple point stabilization for Balanced Rotation

Engineered Design Advantages

- Mechanical Bolted Design for increased efficiency & self sufficiency

- Field Replaceable Cutters to reduce down time

- One body for multiple cutting profiles

- Machined Solid Body Welded to Shaft for Superior Strength

- Rear Jets to aid cutting removal & tripping out of hole

The Falcon FR Series Hole Openers are engineered to withstand the high rotational torque and pull forces required to fracture rock. Our Engineering Team deployed the latest developments in software design, Finite Element Analysis, materials and manufacturing processes to deliver this turnkey solution that can go from pilot hole to 24″ in a signal pass. This simple yet incredibly strong design gives you the flexibility to use one body for multiple cutting profiles.

Built in stabilization features results in a well-balanced tool machined to exacting standards. Interchangeable jet nozzles, job specific front stabilizers and rear stabilizers for increased strength and easy borehole removal are integral components of every Century Hole Opener.

A full line of Tungsten Carbide Inserts (TCI) and Milled Tooth cutting structures are available for a wide variety of formations. Gage protection features for longer in-gage bit life along with Shirttail/Leg Protection for superior wear resistance are incorporated into our Falcon FR Series Hole Openers. The Milled Tooth design uses the most advanced metals to attack the toughest applications.

Diversified Market Segments

Incorporating innovative features into every Century Hole Opener is the focus of Century’s R & D. With worldwide sales across the Americas, Europe, Middle East, Africa and the Pacific Rim, Century’s Hole Openers reach diversified markets in the Oil, Natural Gas, Water and Sewer Industries.

Expect and Demand the Best – That is what we offer!