Arm & Cone Advantages – Gold Series

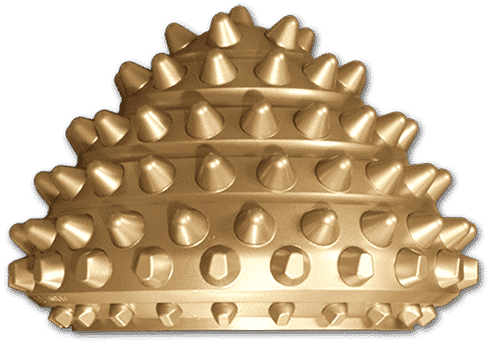

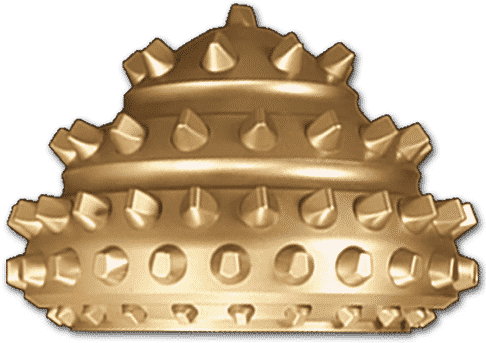

Century’s Replaceable High Load / High Energy Bearing Design comes in both Tungsten Carbide Inserts (TCI) and Milled Tooth configurations. Three different cone sizes are available in our Gold Series, 17″, 22″ and 26″ with three different cutting structures incorporating TCI Conical and Chisel profiles as well as Milled Tooth.

Century Cone Profiles

|

|

|

||

| C38 Conical | C27 Chisel | Milled Tooth | ||

|

|

|

Century Arm & Cone Advantages

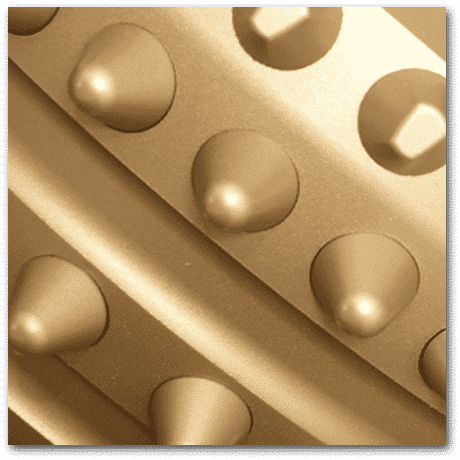

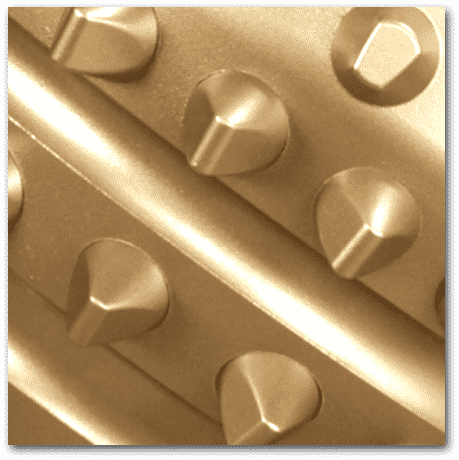

- HSN O-Ring Seals – For the high energy required, Century has designed and utilizes the largest seal in the industry. HSN Material utilized for wear, heat compression and chemical resistance properties.

- Premium Crowned Roller Bearings – Gives the bearing the capability to withstand the extreme high loads.

- Premium Floating Thrust Bearing – Allows for reduced frictional heat build-up to ensure lower operational temperatures under high-energy operations. This design facilitates the longer bit life Century’s reputation has been built around.

- Gage Row Protection – Double the number of carbide inserts that actively cut the gage diameter and assist in maintaining tight tolerances and extending in-gage bit life.

- Shirttail/Leg Protection – Hard Facing along with carbide inserts blanket the shirttail and leg providing superior wear resistance.

Century Arm & Cone Assemblies

|

|

|

| 17″ C38 Conical | 22″ C27 Chisel | |

|

|

|

| 22″ Milled Tooth | 26″ C27 Conical |